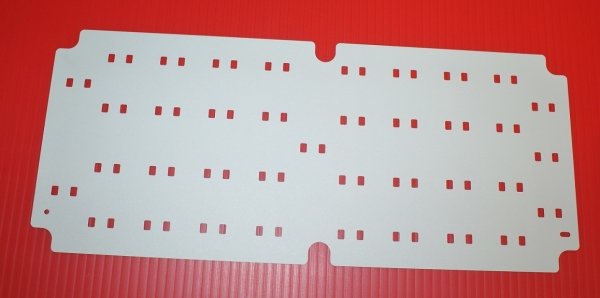

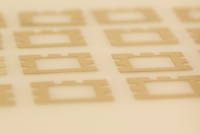

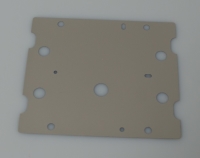

Custom Cut Epoxy Preforms

Bonding Source has shipped millions pre-forms worldwide and offers quick delivery from our in-stock epoxy film selection. Bonding Source maintains complete control with on-site laser cutting capability and stringent inspection criteria. We process small quantity orders (1-5 pieces) and large volume orders (+10,000 per month). Bonding Source is the qualified supplier of choice for the defense electronics and RF/Microwave industries.

- Choose the epoxy film or solder sheet from the Bonding Source in-stock selection. If we do not stock the required film type, Bonding Source can procure it directly from the manufacturer.

-

- Email us the CAD data as a dwg or dxf file.

- Need help creating a preform drawing? Link here: Preform Drawing Guidelines and Template

Bonding Source can also create the preform drawing for you.

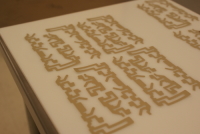

- The drawing is reviewed for fine feature areas, tolerance capability and will be laid out to maximize epoxy sheet usage.

- The pallet file is then sent to the laser and the pre-form is cut. The file will be kept with Bonding Source, under revision control, to facilitate future orders.

- The pre-forms are then inspected on our Microvu inspection system that provides inspection data on all pre-form dimensions. Once programmed, the Microvu system automatically inspects the pre-forms to ensure they are in dimensional tolerance. Watch video of the inspection process here: Preform Inspection Video

- The pre-forms are then inspected for cut quality and cleanliness

- Completed pre-forms will be shipped on cold packs per the manufacturer's specifications to minimize cracking.

- Bonding Source can package and label pre-forms per specification, and accepts blanket orders to match your internal manufacturing schedule.

- First article samples and AS9102 FAI Reports can be provided before proceeding with production quantities.

About Laser Cutting

The microelectronics and RF/Microwave industry have been using laser cut epoxy pre-forms for years. Our laser cutting process has been qualified by Northrop Grumman, Lockheed, Raytheon, Cobham, Exelis, and host of other RF module suppliers. The laser cut system has many advantages:

- No expensive NRE tooling cost.

- Speed and flexibility. There is no long lead time for a die cut tool. If there are changes needed, the CAD data is easily adjusted to accommodate required modifications.

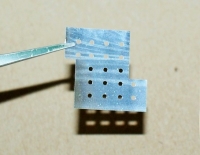

- Best choice for intricate features and tight tolerances.

- Economical for both short and long runs.

- Multi-up pre-forms of different shapes and sizes on individual sheets.

- The process of choice for many defense electronics and high reliability programs.

- Bonding Source utilizes two custom built CO2 Dual Head Lasers made exclusively for the cutting of epoxy and solder pre-forms. A third single head laser is used for cutting other materials, including microwave absorbers, EMI shielding, kapton, silcon press board, teflon and thermal interface material.

- We have established cut profiles for over 50 different epoxy types and thicknesses. The laser processing, inspection, and material handling areas are under "sticky mat" control to minimize FOD.

- To review a copy of the White Paper on the advantages of laser cutting vs. die cutting link here: Laser Cutting White Paper